Shifting Gears: The Future of Industrial Robotics

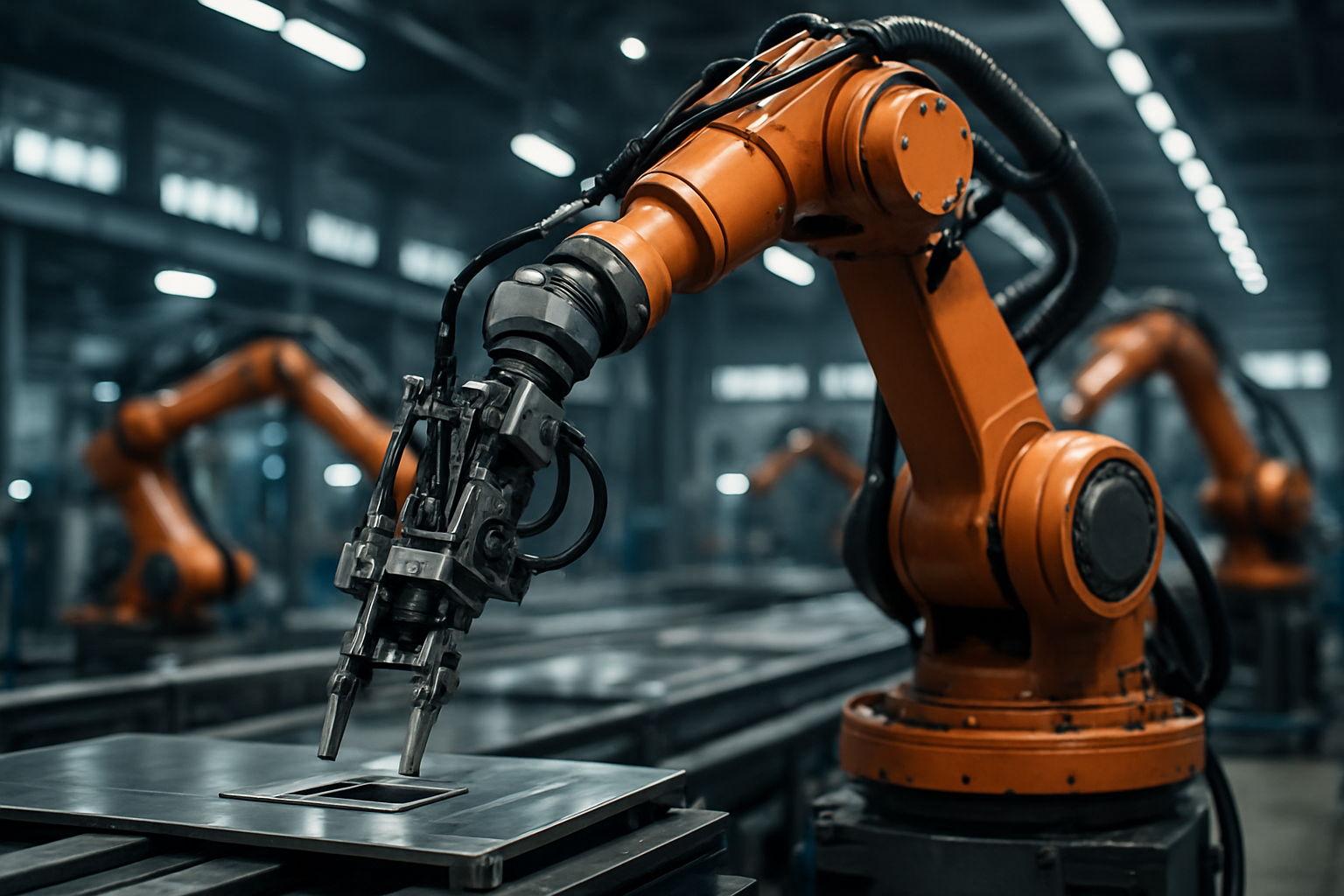

Industrial robotics is no stranger to the world of manufacturing. From the moment the first robotic arm – Unimate was introduced in the 1960s, the world has seen a significant shift in the operational landscape of industries. The past decade, however, has brought about a new wave of interest in these automated machines, thanks to the advancements in technology and computing power. This article explores the rise of industrial robotics, the current trends, and how businesses can navigate these changes.

The Genesis and Evolution of Industrial Robotics

In 1961, the first industrial robot, Unimate, was installed at a General Motors plant, marking the beginning of a new era in automation. This robotic arm was designed to perform simple tasks, such as picking and placing items. Over the years, industrial robots have evolved significantly, becoming more sophisticated, efficient, and capable of performing complex tasks.

Current Trends in Industrial Robotics

The field of industrial robotics is currently experiencing a boom, with robots becoming more versatile and intelligent. Modern industrial robots can now perform tasks that require fine-tuned precision, such as assembling delicate electronic components, as well as tasks that require strength, such as lifting heavy items. Furthermore, the rise of collaborative robots or ‘cobots’ is changing the way humans and robots interact in the workplace.

The Impact of Industrial Robotics on Business Operations

Adopting industrial robotics can bring about a variety of benefits for businesses. These include increased productivity, improved quality control, and the ability to perform dangerous tasks without risking human safety. However, the adoption of industrial robotics also presents challenges, such as the need for significant upfront investment and the potential displacement of human workers.

The Future of Industrial Robotics

The future of industrial robotics looks promising, with advancements in AI and machine learning paving the way for smarter and more autonomous robots. These advancements could lead to robots that are capable of learning from their environment and making decisions independently.

Navigating the World of Industrial Robotics

-

Businesses should consider both the short-term costs and long-term benefits when deciding whether to adopt industrial robotics.

-

Companies should invest in training programs to help their employees adapt to working alongside robots.

-

Businesses should stay informed about the latest developments in industrial robotics and be prepared to adapt their strategies as the technology evolves.

Industrial robotics represents a significant opportunity for businesses to improve their operational efficiency and competitiveness. While the adoption of this technology presents challenges, the potential benefits make it a worthwhile investment. Businesses that can navigate these changes effectively will be well-positioned to thrive in the future.